Our test center

Our philosophy

We work with high level athletes in each discipline to develop the best fins.

After a theoretical approach, we create different prototypes that will be tested.

At each stage, we validate some data and modify others to finally come up with a fin that perfectly meets the athletes' expectations.

Making a carbon or fiberglass blade is not that difficult. Making a performing and durable one is much more difficult and then to work out a swimfin with an excellent blade, the relevant footpocket and a perfect fit between them is a long years quest.

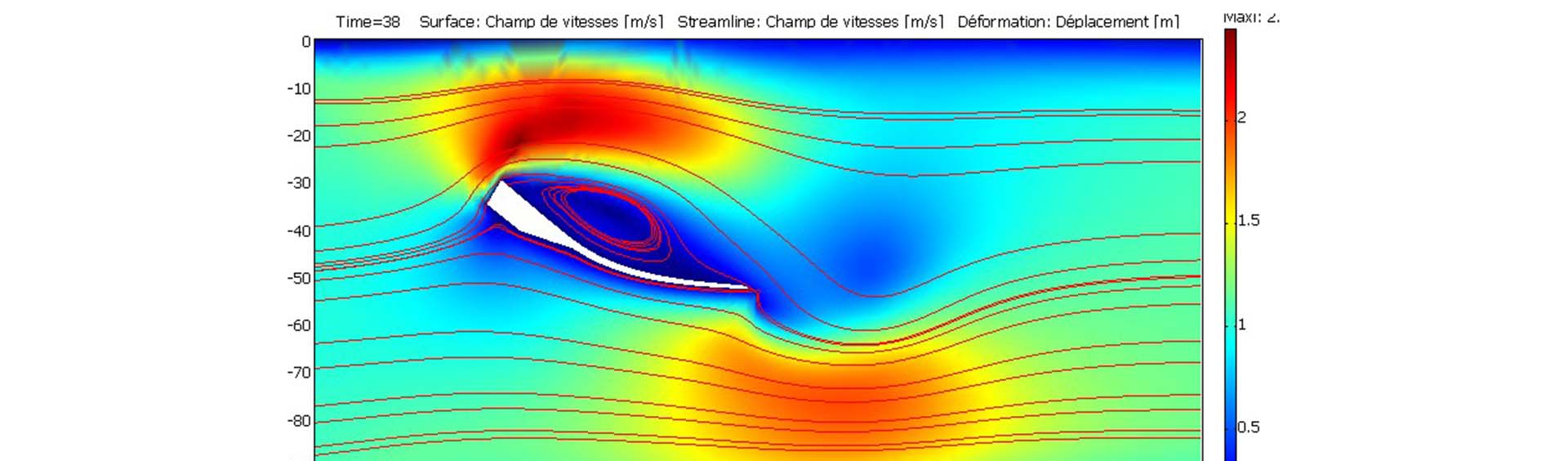

To design a swimfin it is necessary to understand the constraints of the activity and the needs of the athletes. To answer this specifications, we will manage different parameters:

The swimfin’s length: the longer the fin, the more the blade will work by itself and the less effort it will take to move, but conversely, it will be less manageable, heavier and more expensive.

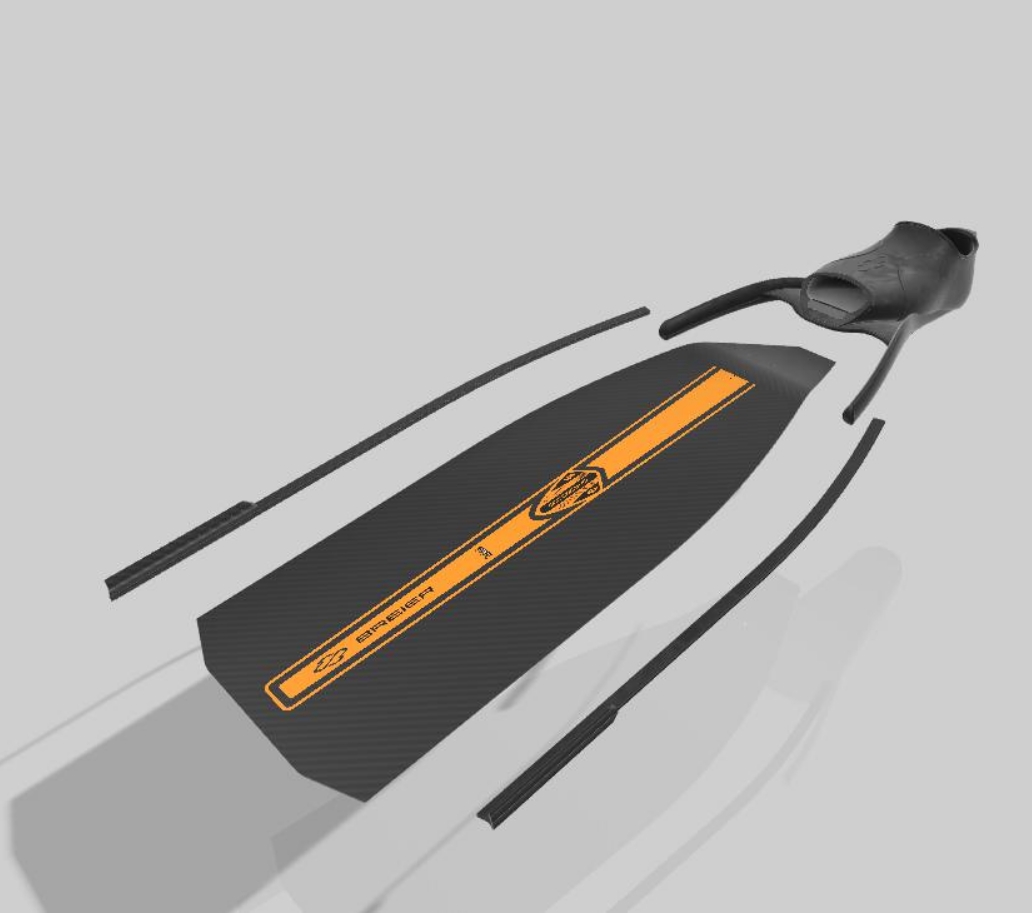

Choosing the right composite: We use pre-impregnated fabrics with an epoxy resin matrix and fiberglass or carbon fiber reinforcements. This one ensures a better return of energy but it is more expensive than fiberglass. The fiberglass S has a better torsional strength. Each fabric has a different weight that will provide more or less rigidity once cooked.

Choosing the right weave: Weaves are also different, twill, taffeta … each has different mechanical properties. And finally, how the fibers are placed relative to the bending direction (45°, 90°) will also affect the strength and efficiency of the fin.

Structure: We assemble several layers of pre-impregnated. Their shape, nature and positioning will allow to obtain up to 6 different hardnesses for the same model. Hardness is fundamental when using a swimfin. Just like shifting gears for the cyclist, a kick with a hard swimfin will allow a great move but will consume a lot of energy, Conversely the same kick with a very flexible fin will generate a more limited move that will have to be compensated with a higher frequency. Unlike the bike, you can’t change your cogwheels, so you have to choose a hardness that is well adapted!

The water rails: they protect the edges of the blade but according to their shape, their hardness and their length, they will also play a role of drift to guide the fin.

The decorations: they are integrated into the blade before the heat curing cycle, in addition to the aesthetic aspect, placed on the heel side, they will enhance safety by providing better visibility. The footpocket, as important as the blade. It must be both comfortable and ensure the most efficient transmission of energy to the blade.